As the term “control tower” gains momentum and extensive attention in the logistics industry, the present blog will provide a more in-depth review of control towers to the readers, based on CapeGroup White paper entitled “Supply Chain Control Tower“,on topics such as:

- Definitions & Advantages;

- Real-life examples of Control Towers implemented in actual companies;

- Impact & Success Factors;

- Technology;

- Top 5 Main Capabilities of a Supply Chain Control Tower

First of all, the modern supply chain control tower is a result of the integration of 3 main elements: People, Methodology and Technology. People bring the actual knowhow and knowledge, but also creative and innovative ideas to build upon with their skill-set. However, all the human potential needs to be structured, coordinated and focused into one specific direction, which is the Methodology and consists of collaboration, the design of the business process and also agreeing on the gains and risks sharing. Now that we have People and Methodology, the potential can be realised only by Technology, which is the supply chain data.

Understanding the first 3 fundamental elements, the control towers capabilities include among others the following:

- End-2-End Supply Chain Visibility;

- Capability to respond and adapt to disruptions;

- Multi-tier process orchestration and supply chain collaboration;

- Predictive decision-making and dynamic supply chain execution

Additionally, how could control towers actual benefit the supply chain? Well, according to the white paper, the following advantages have been researched and identified:

- Reduced time to problem resolution => generate alternatives in seconds;

- Cost savings in supply chain operations;

- Holistic cross supply chain view;

- Maximum agility (speed, reliability, flexibility);

- Optimal asset utilisation;

- Focus & Service critical relationships;

- Risk Mitigation: fast recovery in case of disruption

Second of all, for what functions and which companies do actually use control towers? The control tower is used by 3PL’s for functions such as the management of subcontractors and Vendor Management Inventory (VMI). Furthermore, the 4PL’s and the 5PL’s also use the control tower to monitor closely the execution and to facilitate the orchestration of the multiple networks and supply chains which they manage. A comprehensive market overview with all current companies which use control tower to manage their supply chains, include the following companies:

Third of all, considering that the definitions are clear, the benefits are provided and the actual companies that use control towers are mentioned, the questions are:

- What could the actual impact on your supply chain be if implementing control tower capabilities?

- What are the main learnings, or success factors, from all the trials and errors, which could facilitate an improved implementation of control towers in your company?

Well, the reader should note that the impact varies per each individual supply chain and network, and only general researched and proven impacts are shared as such. After a company decides on implementing a supply chain control tower, the potential impacts could be the following:

- Facilitate trust, collaboration, and sharing data with trade partners;

- Paradigm shift: cross-functional approach (no more silos);

- Gain sharing with trade partners: costs & profits;

- In-depth insights into business & supply chain processes;

- Adjustments in legal contracts & trading terms;

Answering the second question, the critical success factors that need to be taken into consideration by any firm, company or organisation, before actually implementing the supply chain control are the following:

- Top Management Leadership & Support;

- Change Management;

- Incremental approach: one step at a time;

- One shared & agreed Business Case;

- Willingness to share profits, costs and risks;

- Data Security;

- Product ownership: secure personnel & knowhow

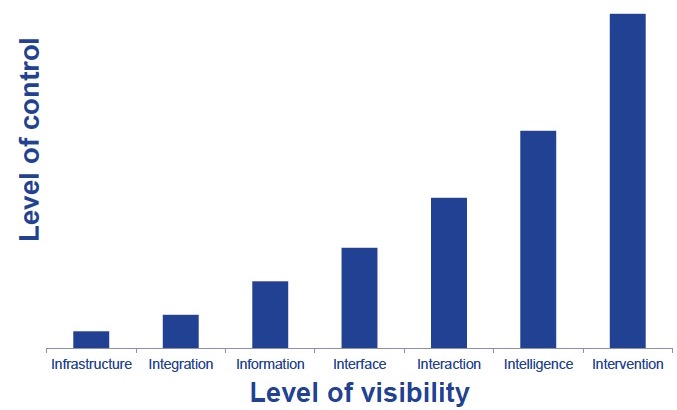

Fourth of all, what are the levels of control and visibility that a supply chain control tower can provide, and how can it be ranked and visualised accordingly? It is important to mention that there are seven levels of control & visibility, starting from basic Infrastructure and all the way up to Intelligence and Intervention when the supply chain control tower gains the ability to take the best-scenario decisions on its own, without any human support or intervention.

Finally, the fifth mini-chapter of our blog today concludes by providing the readers with the Top 5 Main Capabilities of a Supply Chain Control Tower, which are translated as the main detailed functions of tangible impact within any supply chain. An overview of the top 5 main capabilities, include, among others the following:

- End-2-End Supply Chain Visibility;

- Planning Optimisation;

- Event & Change Managent;

- Advanced Reporting & Analytics;

- Responsive, multi-devices interfaces

In conclusion, the white paper on “Supply Chain Control Tower” was briefly discussed, by presenting a main summary on the most important aspects, such as definitions & advantages, examples of companies using this module, impacts & success factors, the levels of control & visibility and finalising with the Top 5 Main Capabilities.

In my opinion, I believe that one of the most critical success factors before adopting and implementing a supply chain control tower consists of trust and sharing of data & knowledge among supply chain and trade partners. I think that the trust issue is the biggest challenge. Additionally, the misuse of data and non-disclosure agreements result in a complex challenge which currently all the transport companies and multinationals face nowadays. Once this issue is agreed upon and solved, the capital, knowhow and leadership will ensure a successful implementation of a supply chain control tower solution.

I believe that the main contributing factor for ensuring trust is previous successful collaboration. This means that if two companies want to set-up a supply chain control tower together, they must have done Win-Win business with each other for at least 1-5 years before. In this way, familiarity is ensured, relationships are extended, and agreements are made. As a result, I think that it is natural to resist trusting and sharing information parties with whom business has not been done at all.

I would like to end this blog by saying that I firmly believe that the supply chain control tower functions can optimise the supply chain by reducing costs and mitigating risks, while ensuring excellent customer service, order reliability and execution. I think that the supply chain control tower provides a significant competitive advantage and that this should be the norm / standard, for all the modern transport companies and multinationals.